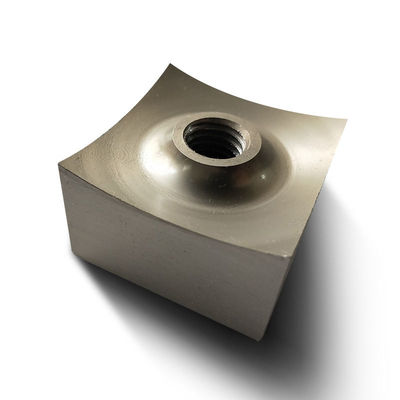

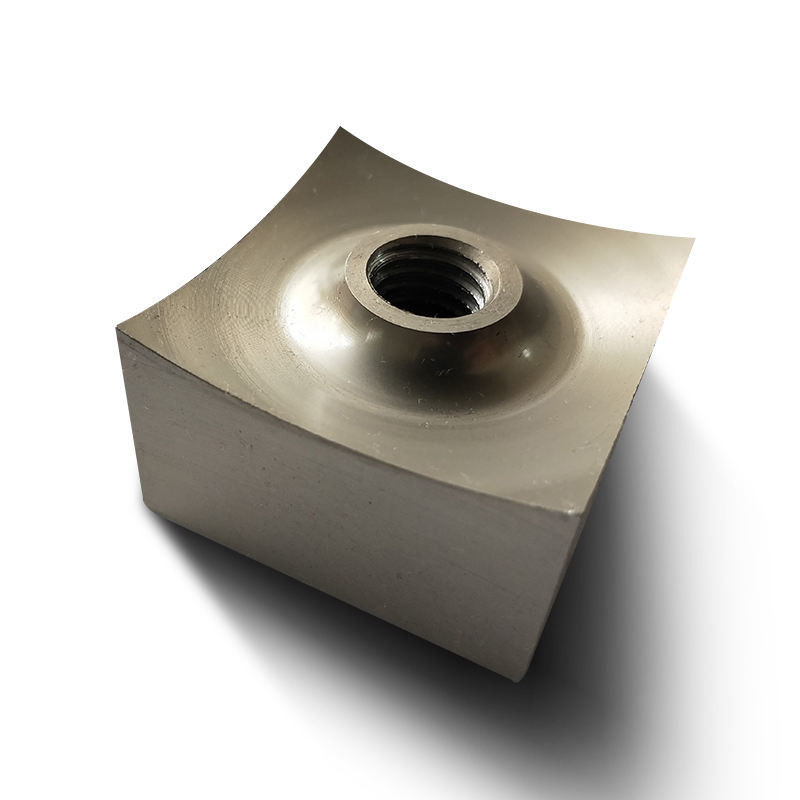

Double Shaft Metal Shredder Blades A10 9CrSi Cr12MoV

Product Details:

| Place of Origin: | China |

| Brand Name: | Liangru |

| Certification: | ISO9001 |

| Model Number: | OEM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Packaging Details: | anti-rust oil in plastic bag, Packed in strong plywood cases |

| Delivery Time: | 30-35days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

|

Detail Information |

|||

| Name: | Cut To Length Shear Knives | Other Blade: | Coil Shear Blade, Straight Cutting Blade |

|---|---|---|---|

| Material: | A10,9CrSi, Cr12MoV Etc | Size: | Max Length Is 6000mm |

| Hardness: | HRC58-62 | Application: | Galvanizing Lines |

| Highlight: | Double Shaft Metal Shredder Blades,shredder replacement blades 9CrSi,Metal Shredder Blades A10 |

||

Product Description

Double Shaft Metal Shredder Blade

2. Long lifespan and stable performance

3. Good cutting result and high efficiency

1. the hardness of the blade to ensure the good quality.

2. We check the flatness degree to see if it is up to standard.

3. We also do some cutting experiments to check its using function.

4. Professional manufacturing assembly line

|

Product Name

|

Shredder blade

|

|

Product Material

|

9crsi,SKD-11,Cr12MoV,H13(Customize according to customer requirements)

|

|

Product Size

|

OEM/ODM

|

|

Hardness

|

58-60HRC(By the material selected)

|

|

Product Precision

|

OD:+0.1,ID:+0.03-0.00,Thickness:+0.03

|

|

Product packaging

|

Wooden case packaging

|

|

Product Use

|

Cut and tear

|

Popular size of the galvanized sheet Exit Shear Knife:

| 1245x80x25 | 508x70x22 | 1026x63x16 |

| 1545x80x45 | 508x80x25 | 1300x80x20 |

| 540x70x22 | 505x70x22 | 1100x80x20 |

| 508x80x25 | 1300x63x16 | 1025x80x20 |

![]()

Advantages:

- 100% inspection

- No deformations after shearing

- Smooth cut-off edges

- No burrs on the edge after shearing

![]()

Our Services & Strength

1. According to the materials provided by the customer, choose 6 kinds of imported steel and 8 kinds of domestic high-quality steel.

2. The heat treatment adopts the domestic leading equipment and technology, with the following options: vacuum quenching, high-frequency quenching and salt furnace quenching.

3. Three elements of quality control and quality assurance: material selection, heat treatment and precision.