Plastic Rubber Waste Tyre Recycling Shredder Knive Shredder Blades Crusher Blade

Product Details:

| Place of Origin: | China |

| Brand Name: | Liangru |

| Certification: | ISO9001 |

| Model Number: | OEM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Packaging Details: | anti-rust oil in plastic bag and Packed in strong plywood cases |

| Delivery Time: | 30-35days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

|

Detail Information |

|||

| Name: | Guillotine Shear Blade | Other Blade: | Metal Shear Blade,cross Cutting Blade,straight Cutting Blade |

|---|---|---|---|

| Material: | HMY | Size: | Max 6000mm Length |

| Hardness: | Range: HRC51-65 | Application: | Cut To Length Line,slitting Lines |

| Highlight: | Plastic Rubber Shredder Blades,Tyre Recycling Shredder Blades,Crusher Blade Shredder Blades |

||

Product Description

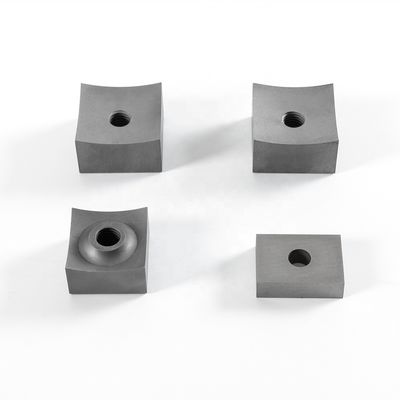

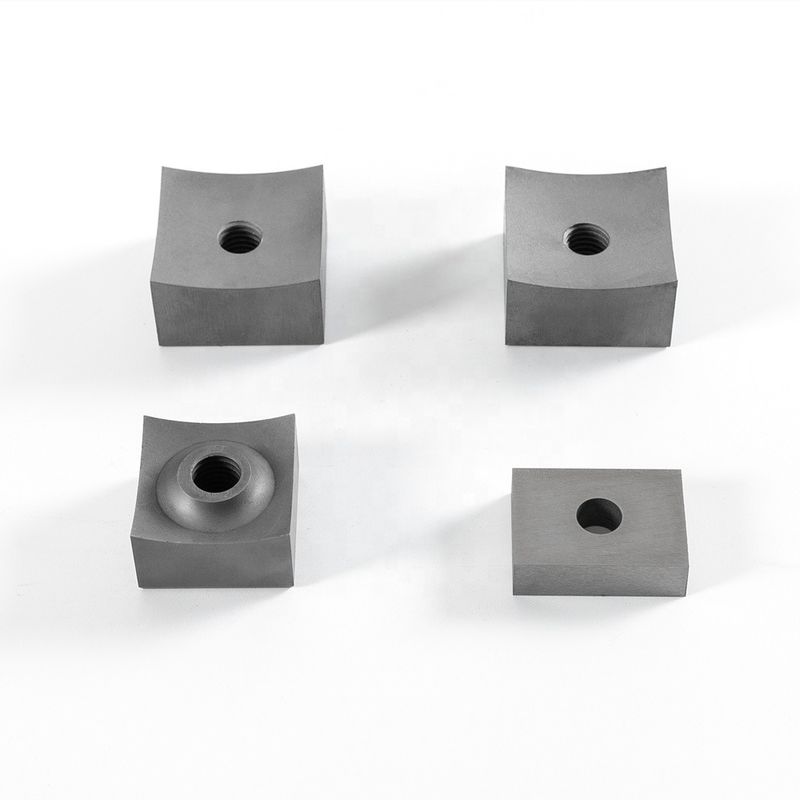

Plastic Rubber Waste Tyre Recycling Shredder Knive Shredder Blades Crusher Blade

The double shaft shredder machine is capable of handling most material such as the bucket, basin, drum, aluminum cans, cartons papers, etc. and it is widely used in various fields as an effective solution with capacity up to 3T kg/h.The blades are very important parts for the shredder machine. We can make the blades according to the buyer's drawing

- The adoption of high quality knife material combined with advanced vacuum heat treatment and Cryogenic treatment process enables our knife become the leader in the world and deeply favored by customers in Europe, America, Australia, Japan and Korea, etc.

- Our advantage lies in the fact that we can provide customized service by selecting the most suitable tool material and adopting the most accurate heat treatment process to ensure the utmost performance of tool according to the application and performance required by customers.

- Our large vacuum heat treatment furnaces, forging, CNCmachining and other high quality facilities necessary to production guarantee our first class quality.

| Product Type | Shredder Blades |

| Material | HSS; SKD11; SKD61; Cr12Mov; or selected by the customers |

| Hardness | 58-60 HRC (by the material selected) |

| Dimension tolerance | OD:±0.1, ID:±0.03 -0.00, Thickness: ±0.03 |

| OEM service | Available |

| Main market | Western Europe, Southeast Asia |

Advantages of guillotine shear blade for cross cutting machine:

1. Senda Guillotine shear blades can shear metal materials generally reach 9000~15,000tons for one time sharpening to ensure the productions and lifetime without edge broken.

2. New HMY material , perfectly shear 3-16mm high strength steel coils at the same time.

3. Liquid nitrogen -196degree cold treatment ensure the hardness and toughness

4. vertical pit furnace ensure the heat-treatment.

Application of the carbon steel coil guillotine shear blade:

1. Normally for hot rolling: 3~12mm carbon steel coils etc.

2. Normally for cold rolling: 0.2mm~3.2mm carbon steel plates, galvanized plates etc.

3. popular size:

| dividing shear | 3500×170×100; 3500×150×100; 3200×180×80; |

| double side shears TOP | 2080×170×100, 2200×170×100 |

| double side shears BOTTOM | 2075×160×70, 2200×150×100 |

| shear blade | 2600×220×70; 3400×220×70; 3500×200×60 ; 2100×162×65; |

| 2100×150×65; 2650×150×40; 2800×205×100; 2800×150×100 |

![]()