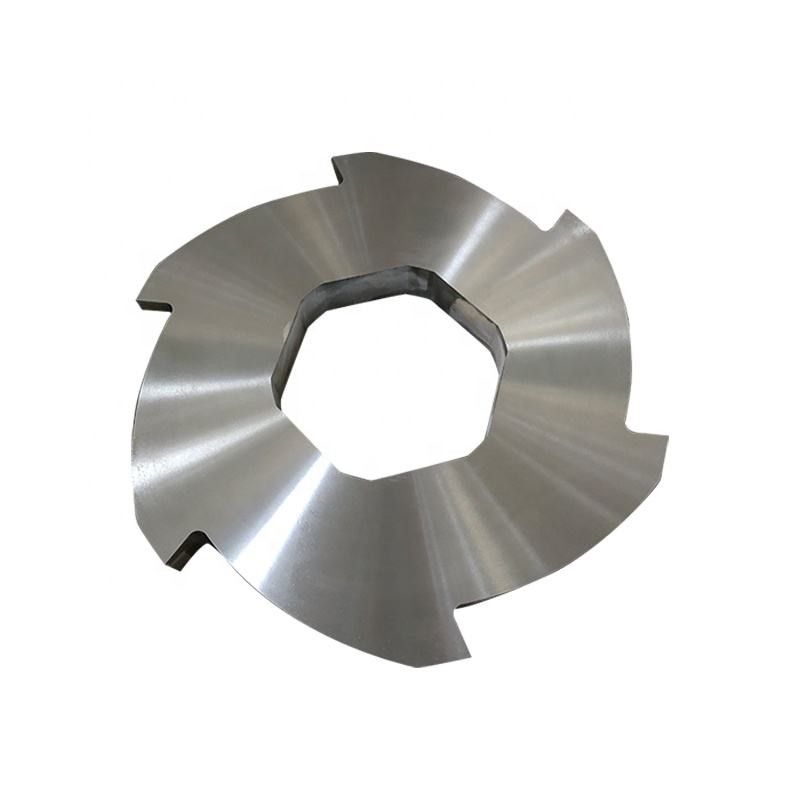

Circular K110 Rotary Slitter Cutter Blades 0.02mm Flexible Rolling Shear

Product Details:

| Place of Origin: | China |

| Brand Name: | Liangru |

| Certification: | ISO9001 |

| Model Number: | OEM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2pcs |

|---|---|

| Packaging Details: | anti-rust oil in plastic bag,Packed in strong plywood case |

| Delivery Time: | 30-35days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

|

Detail Information |

|||

| Name: | Rolling Shear Blades | Other Name: | Rolling Shear Knife |

|---|---|---|---|

| Material: | SKD11,D2, M2, K110 | Packing: | Plywood Case |

| Inner Diameter: | +0.02mm | Flatness: | ≤0.002mm |

| Parallelism: | ≤0.002mm | Concentricity: | ≤0.02mm |

| Surface Roundness: | Ra0.1um | Hardness: | Tool Steel: HRC58~61 |

| Highlight: | Rotary Slitter Cutter Blades,fabric rotary cutter blades,K110 Cutter Blades |

||

Product Description

Circular K110 Rotary Slitter Cutter Blades 0.02mm Flexible Rolling Shear

Product description:

Slitting tool is mainly used for metal slitting production and processing line, the raw material of the blade is made of high speed cutting tool steel SKD11, SLD, SKH51, H12, H13, DC53 and other precision machining. Especially suitable for all kinds of cold and hot rolled steel sheet, pickling sheet, silicon steel sheet, stainless steel, silicon steel sheet, steel strip and other high-speed cutting and slitting production.The slitting blade is the most important part of the production process. The precision of the slitting knife is very high. For the blade plane, we use precision grinder, after forging, mechanical processing, heat treatment, and then by special grinding, and through strict quality control to ensure that the parallelism of all finished products is within 0.003mm.

- Country of Origin: China

- Material: SKD11,D2, M2, K110

- Size: Customized

- Thickness tolerance: +- 0.001mm

- Inner Diameter: + 0.02mm

- Flatness: ≤ 0.002mm

- Parallelism: ≤ 0.002mm

- Concentricity: ≤ 0.02mm

- Surface roundness : Ra 0.1um

- Hardness: Tool steel: HRC56~~58

- Packaging: wooden box with anti-rust film inside

- Application: electrolytic tinplate coating lines

Application of the rolling shear blades for tinplate coating line:

1. for hot rolling mills: 1~12.7mm carbon steel coils and plates

2. for cold rolling mills: 0.02 ~3.2mm carbon steel plates and plates

![]()

Steel choosing→Blanking →Forging Steel →Rough Processing →Heat treatment →Finishing→Testing